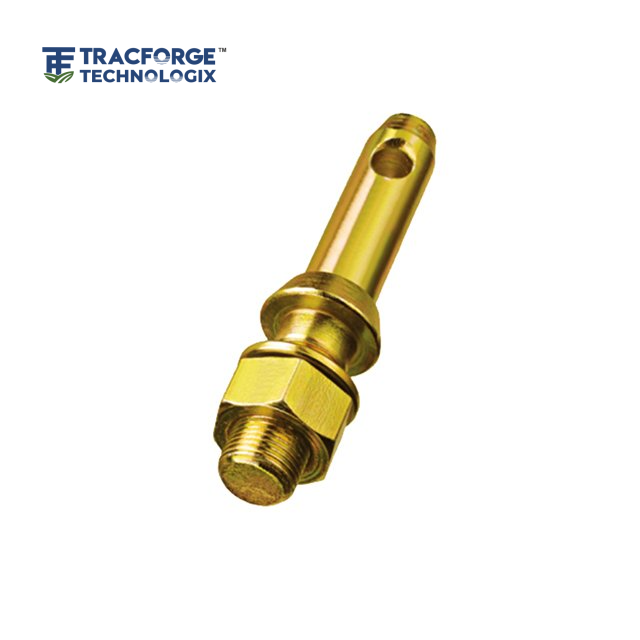

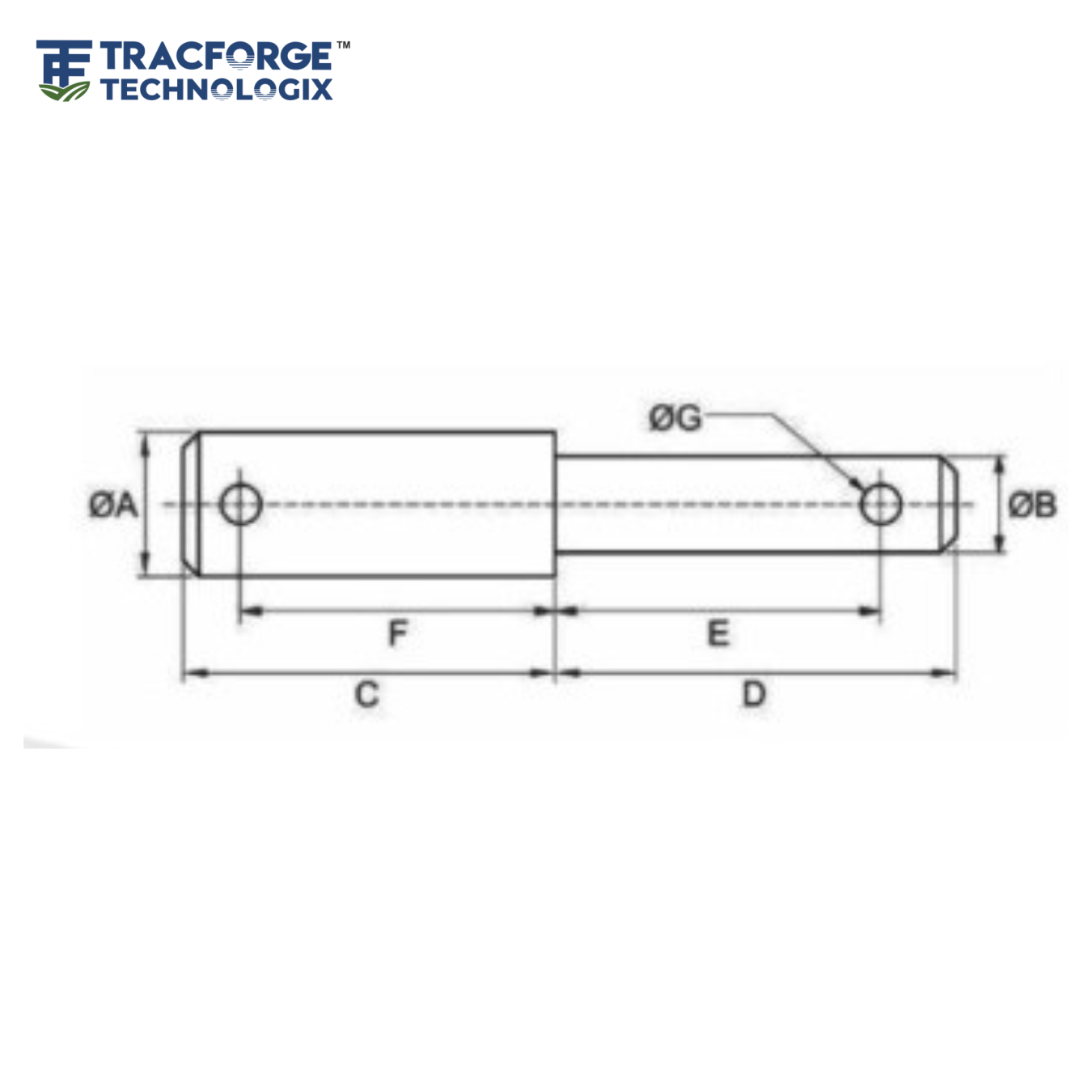

Weld on End Mounting Pin

| CODE | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|

| TGF0 | 28 | 22 | 62.5 | 84.5 | 70.5 | 47 | 12 |

| TGF1 | 28 | 22 | 76.5 | 104.5 | 88 | 60 | 12 |

| TGF2 | 28 | 22 | 85 | 105 | 85 | 62 | 12 |

| TGF2 (Alt.) | 28 | 22 | 103 | 78 | 60 | 87.3 | 12 |

| TGF4 | 28 | 22 | 120 | 56 | 39 | 92 | 12 |

| TGF5 | 28.6 | 22 | 76 | 105 | 87.3 | 60 | 12 |

| TGF6 | 34 | 28 | 61 | 80 | 62 | 43.5 | 12 |

Quality You Can Trust

ISO 9001

Quality Management System certification ensuring consistent product quality.

ISO 14001

Environmental Management System for sustainable manufacturing practices.

OEM-Grade Fitment

Guaranteed compatibility and performance meeting original equipment standards.

Product Description

The Weld-On End Mounting Pin is engineered for applications where a permanent, welded mounting connection is required. Ideal for fabricators, implement manufacturers, and repair workshops, this pin offers exceptional strength and precision, ensuring reliable performance in demanding agricultural environments.

Manufactured from high-grade steel, each pin is fully machinized for smooth bearing operation, accurate alignment, and consistent performance. Its clean, weld-ready surfaces allow easy attachment to equipment frames, loader arms, linkages, and custom-built tractor implements.

The corrosion-resistant finish improves protection against moisture, wear, and field conditions, making it a dependable solution for long-term use.\

Key Features

- Weld-on design for permanent, secure mounting

- Premium-grade steel construction for high load durability

- Precision-machined for smooth performance

- Corrosion-resistant surface for long-lasting protection

- Ideal for custom fabrication, implement repair & OEM production

- Suitable for tractors, trailers, and heavy-duty implements

Explore Related Parts

Request a Quote

- Fast Response Guaranteed