Quality Lab

Quality Lab

Quality Lab

A Quality Lab plays a critical role in ensuring the reliability, durability, and performance of products across various industries. It serves as the backbone of quality assurance by conducting precise testing and analysis of raw materials, semi-finished goods, and final products. Equipped with advanced instruments and technologies, the lab ensures compliance with international standards and customer requirements.

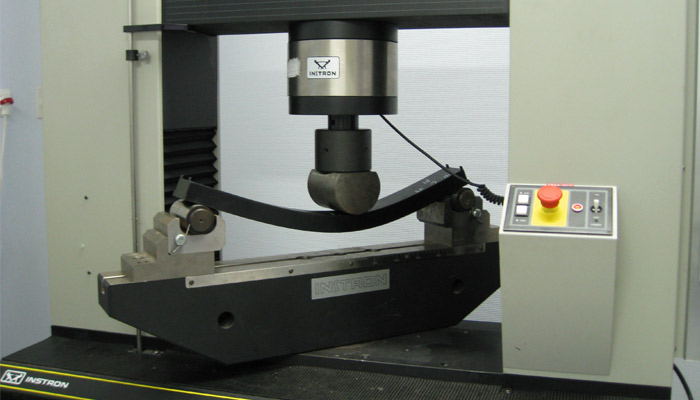

The primary functions of a quality lab include material testing, dimensional analysis, hardness testing, tensile strength evaluation, and surface finish inspection. These tests verify that components meet specified tolerances, mechanical properties, and aesthetic criteria. Specialized equipment such as spectrometers, coordinate measuring machines (CMM), and surface roughness testers are often used to achieve accurate and consistent results.

In addition to routine testing, the lab also plays a proactive role in identifying potential issues during production. By conducting root cause analysis and implementing corrective measures, the lab helps prevent defects, reduce wastage, and enhance overall efficiency.

A well-maintained quality lab reflects a company’s commitment to excellence and customer satisfaction. By ensuring that products adhere to the highest standards, the lab builds trust with clients and reinforces the organization’s reputation for delivering exceptional, reliable solutions.