Our Infrastructure

About us

Our Key Infrastructure Includes

Forging Hammers

CNC Machines

VMC Centers

Hobbing Machines

Induction Hardening Units

Tempering Furnaces

Gas Carbonizing Furnaces

Manufacturing Facilities

Our state-of-the-art manufacturing facilities are equipped with advanced CNC machines, quality testing labs, and skilled technicians to ensure precision and durability in every component.

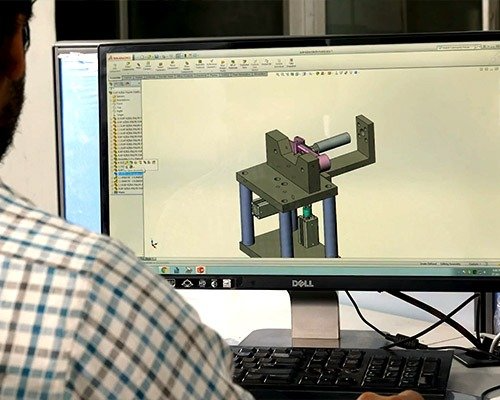

Designed & Engineering

Our products are designed with precision and engineered for performance. Backed by a skilled R&D team, every component undergoes detailed design, stress analysis, and real-world testing to ensure durability and optimal functionality

Inspection & Testing

Our dedicated QA team guarantees that only defect-free components reach our customers, ensuring safety, reliability, and long-term performance in every application.

Our Machineries & Infrastructure

Casting & Forging (In-House)

Our in-house forging facility, equipped with power hammers and upsetters, enables the production of components with superior mechanical strength, refined grain structure, and enhanced durability. Forged parts are ideal for applications requiring high impact resistance and structural integrity.

We also provide high-quality casting services, including SGI (Spheroidal Graphite Iron) and CGI (Compacted Graphite Iron).All castings are produced in accordance with technical standards or custom specifications, ensuring consistent quality and performance.

Precision Machining (In-House)

Our in-house machining facility is equipped with CNC machining centers, lathes, and milling machines, allowing us to achieve high dimensional accuracy and fine surface finishing.

These capabilities are essential for parts used in critical assemblies, where precision and reliability are key. By keeping machining operations in-house, we ensure tight quality control, faster lead times, and seamless production flow—delivering components that meet stringent engineering requirements.

Quality Assurance & Testing

We apply rigorous inspections at every stage of production, from raw material selection to final assembly, to ensure that each component meets the highest standards of quality and precision. Our commitment is to deliver products that perform reliably and withstand real-world conditions in the field.

With fully equipped in-house testing and inspection facilities, we conduct a comprehensive range of tests, including dimensional checks, hardness testing, surface finish inspection, and performance validation. These measures help us maintain strict quality control, reduce defects, and guarantee consistent product performance.

Heat Treatment (In-House Facility)

Our in-house heat treatment facility is equipped with advanced gas-fired and induction furnaces to deliver precision processes like normalization, tempering, and annealing. These treatments enhance strength, durability, and performance under demanding industrial conditions.

We also offer induction hardening for surface strengthening of shafts and other critical components, improving wear resistance and fatigue life while preserving core toughness.

Every process is controlled and customized to ensure the reliability, consistency, and longevity of the parts we manufacture.

Engineering & Product Development (In-House)

Our expert technical team brings deep industry experience and engineering know-how, supported by a fully equipped in-house design and development setup. We specialize in customized product solutions tailored to a wide range of technical and industrial specifications.

Using advanced CAD tools, prototyping techniques, and working in close collaboration with clients, we ensure every solution is precise, functional, and application-ready—from concept to final production.

In-House Zinc Plating Facility

Our infrastructure includes a state-of-the-art Zinc Plating Plant equipped with a Semi-Automatic Zinc Plating Line for uniform and high-quality surface treatment. This setup ensures superior corrosion resistance, enhanced product life, and consistent finish quality. With strict process control and reliable plating systems, we maintain high standards of durability and performance across all treated components.